PRODUCT FEATURES

Pre Painted Aluminium Coil Manufacturer to Rocket Your Business

PRODUCTS

Proud to Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today.

ABOUT US

Who is Upaluminum.com

Upaluminum.com have seen that today there are also many aluminum coils companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and upaluminum.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

The Ultimate Guide to Pre-Painted Aluminium Coil

If you’re in the market for pre painted aluminium coils, you may be wondering what your options are and how to choose the right one for your needs.

This article will give you all of the information you need to make an informed decision about pre-painted aluminum coils, as well as some tips for finding the right manufacturer for your business.

So, if you’re ready to learn more about pre-painted aluminium coils, read on!

Table of contents

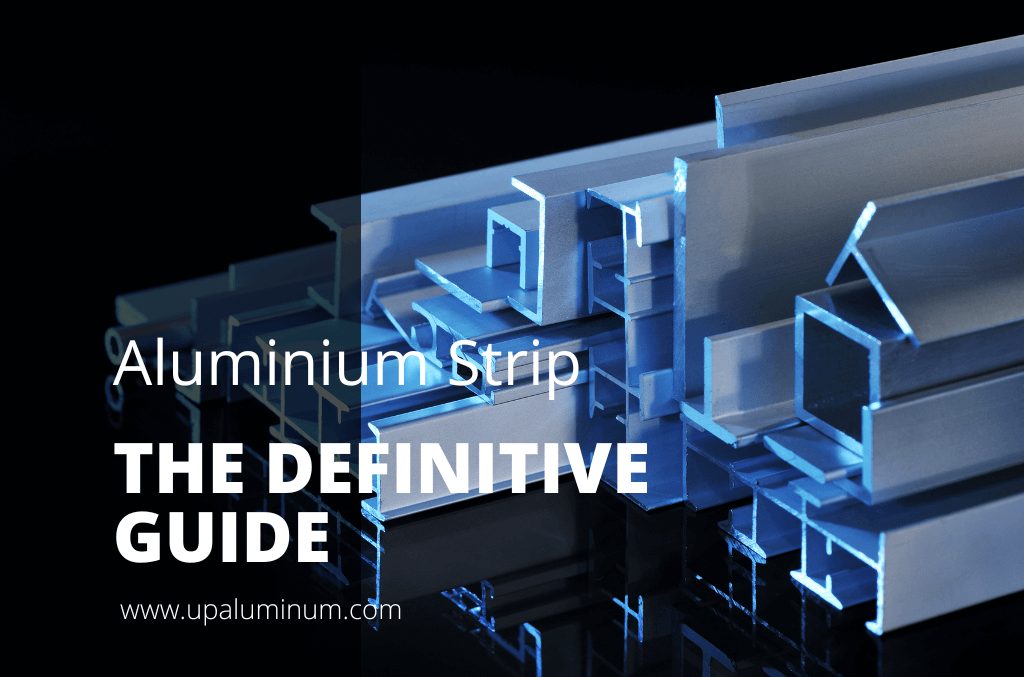

1. Pre-painted Aluminium Coil: The Basics

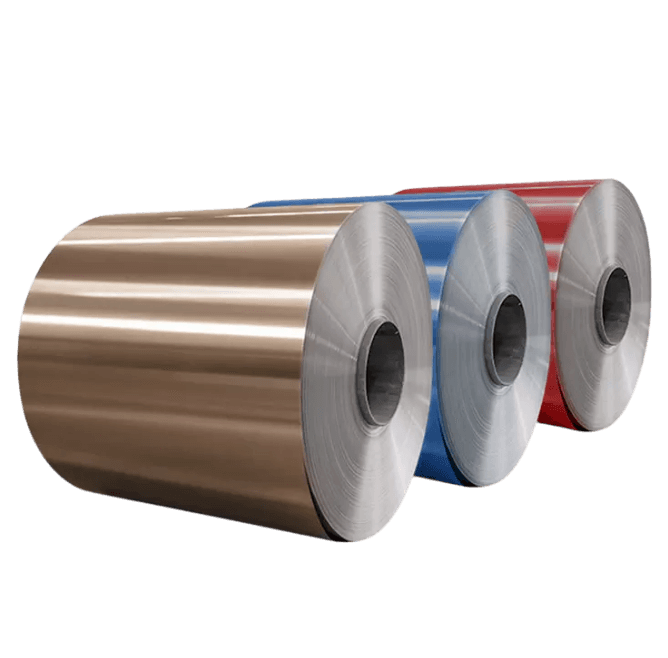

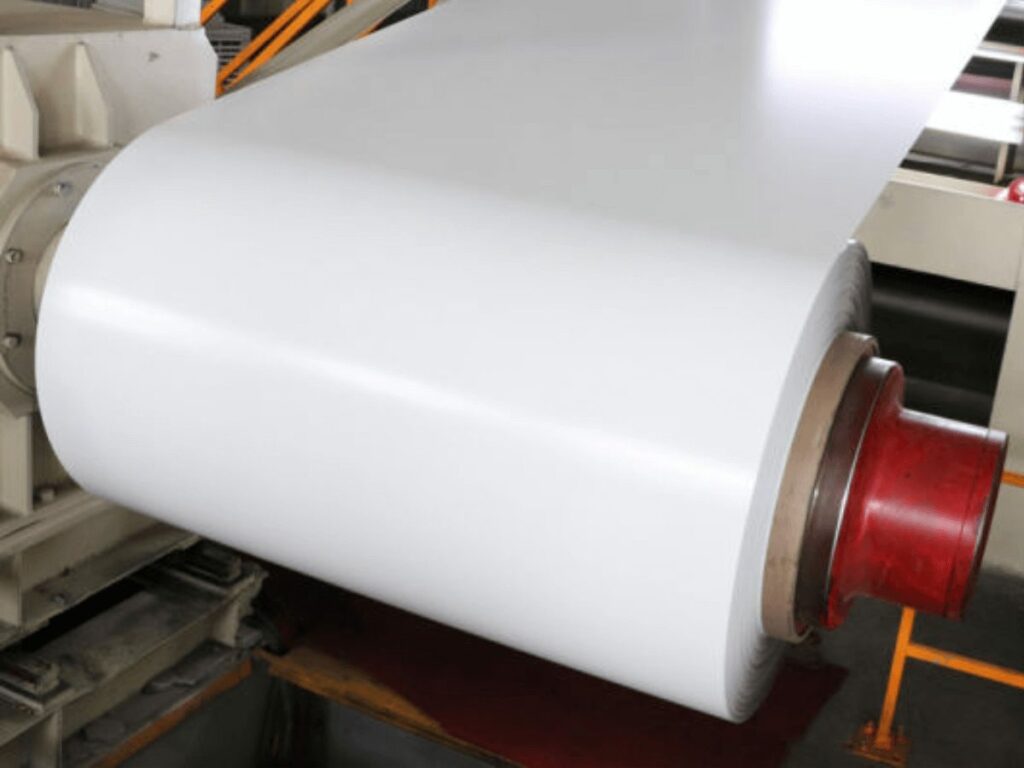

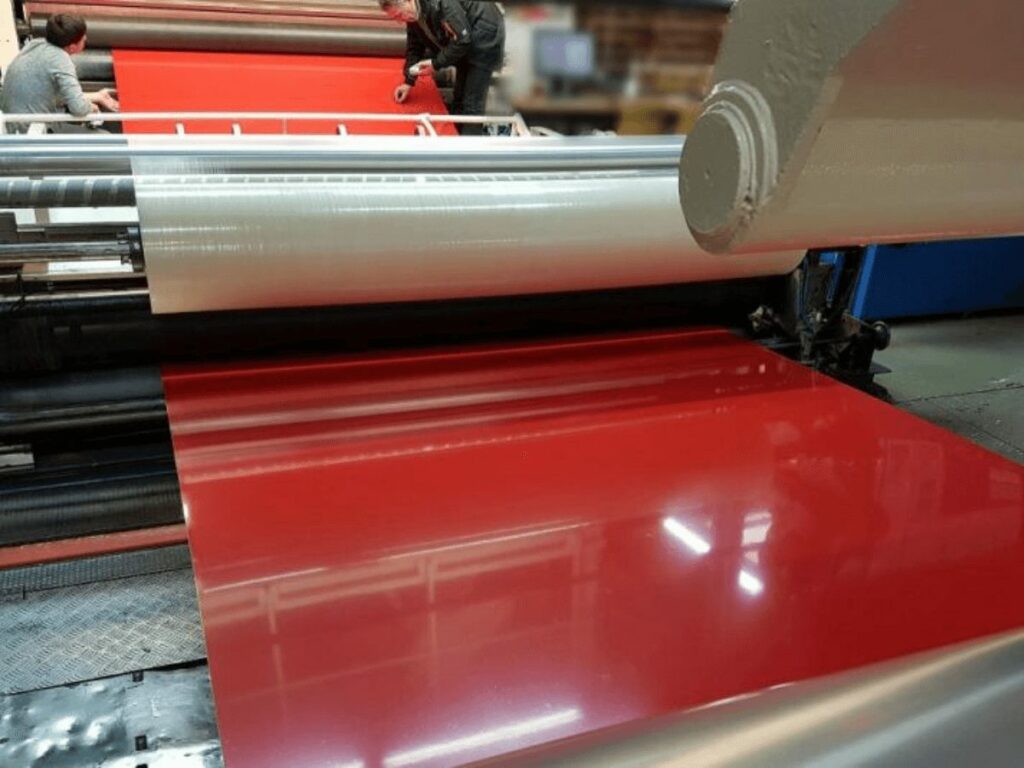

Pre painted aluminium coil is metal aluminium that has a paint layer applied to both sides. It’s produced by running the aluminium through a continuous coil coating process, which creates an even and consistent finish.

It is used in a wide range of industries, from construction and architecture to electronics and appliance manufacturing. In terms of its appearance, the pre-painted aluminium coil can be found in a variety of colors and finishes, making it a versatile material for use in design and decor.

Its functional value comes from its ability to resist corrosion and UV damage, making it an ideal choice for exterior applications. It is also low maintenance and easy to clean, furthering its appeal for use in a wide range of settings.

2. Key Features

Pre-painted aluminium coil is a popular building material for both indoor and outdoor applications. Here are the features that make it so popular:

Lightweight

Aluminium is about one-third the weight of traditional building materials such as steel and concrete. This reduces the overall weight of buildings and facades constructed using pre-painted aluminium coil cladding panels.

Corrosion Resistant

Thanks to the formation of an oxide layer on its surface when exposed to air or moisture, the pre-painted aluminium coil is highly resistant to corrosion. This also means that pre-painted aluminium coil panels require little to no maintenance over their lifespan.

Weather Resistant

Pre-painted aluminium coils are designed to withstand exposure to the elements, including moisture and temperature extremes without warping, fading, or discoloring.

Sustainable

Aluminium is a sustainable building material that can be recycled over and over again without losing its properties. This makes pre-painted aluminium coil an environmentally friendly choice for construction projects.

Aesthetic

Pre-painted aluminium coils are available in a variety of colors, so you can choose the color that best suits your needs. In addition, the coating provides a high degree of durability, so the color will not fade over time.

Durable

Pre-painted aluminium coil is one of the most durable building materials available. It can last for decades without requiring replacement or repairs.

Low Maintenance

Pre-painted aluminium coil require little to no maintenance over their lifespan. This saves time and money in the long run.

3. The Advantages

Pre-painted aluminium coil refers to the product after coating and coloring on the surface of aluminium plate or strip. The main advantages of the pre-painted aluminium coil are:

| High Level of Durability | Pre-painted aluminium coils exhibit a high level of durability. The paint system is extremely resistant to weather conditions such as sunlight, rain, snow, and ice, and will not fade or peel when exposed to these conditions. |

| Versatile Range of Colors | Pre-painted aluminium coils offer a versatile range of colors. A wide variety of colors are available for use on these coils, including metallic colors and bright solid colors. |

| Good Corrosion Resistance | These pre-painted coils offer good corrosion resistance. The paint coat provides an effective barrier against corrosion, which helps to prolong the lifespan of the coils. |

| Easy to Clean | These pre-painted coils offer good corrosion resistance. The paint coat provides an effective barrier against corrosion, which helps to prolong the lifespan of the coils. |

| Cost-Effective | The initial cost of the coils may be higher than other types of coil products, but the long-term cost savings associated with their durability and low maintenance requirements make them a wise investment. |

4. Types of the Surface Coating of Paint

These are the types of surface coatings commonly used in paint. Let’s discuss them one by one.

Epoxy Coating

Epoxy paint is a type of paint that contains epoxy resins as its binder. Epoxy coatings are typically used in high-performance applications, such as those involving direct contact with food or extreme temperatures.

Phenolic Coating

Phenolic resins are created by the reaction of an acid and an alcohol.This reaction produces a durable and hard film that is resistant to both chemical and physical damage. Phenolic coatings are typically used in applications where high temperatures are present.

Polyurethane Coating

Polyurethane paint is a type of coating that uses polyurethane resins as its binder. Polyurethane resins are created by the reaction of a diisocyanate and a polyol.

Acrylic Coating

Acrylic paint is a type of coating that uses acrylic resins as its binder. This reaction produces a flexible, matte finish that can be easily tinted. This makes acrylic paint a good choice for coating aluminum coils, as it will not chip or peel and can withstand exposure to the elements.

Silicone Coating

Silicone resins are created by the reaction of a silicon-containing material and an organic compound. This reaction produces a high-gloss, durable finish that is usually used in applications where chemical resistance is required.

5. Common Industry Applications

Pre-painted aluminium coil is a popular material used in a variety of industries for a wide range of applications. Some of its common industry applications include:

Construction

Pre-painted aluminum coil is frequently used in construction, particularly in cladding and facade applications. The high durability and weather resistance of pre-painted aluminium makes it an ideal material for use in construction projects.

Automotive

It is also commonly used in the automotive industry. Its durability and resistance to corrosion make it an ideal material for use in car body panels and other automotive components.

Electrical

Its conductivity makes it ideal for use in electrical wiring and components. Its resistance to corrosion also makes it an ideal material for use in electrical enclosures and junction boxes.

Consumer Goods

Pre-painted aluminum coil is also used in the manufacture of a variety of consumer goods. Its durability and aesthetic appeal make it an ideal material for use in a wide range of products, from kitchen appliances to outdoor furniture.

Industrial

Pre-painted aluminum coil is also used extensively in various industrial applications. Its resistance to corrosion and high durability make it an ideal material for use in many different types of equipment and machinery.

6. How to Import Pre-painted Aluminium Coil 5 Simple Steps

If you are considering importing pre-painted aluminum coil, here are 5 simple steps to help you get started.

Step#1 Research the Market

To ensure that you can source pre-painted aluminum coils at the best possible price, it is important to research the market thoroughly. This includes investigating the prices charged by different suppliers, as well as the quality of their products.

Step#2 Choose a Supplier

Once you have a good understanding of the market, you can begin to narrow down your choice of supplier. There are many factors to consider, such as price, quality, delivery times, and payment terms.

Step#3 Place Your Order

Once you have selected a supplier, you can place your order and arrange for delivery. Be sure to specify the exact quantity and dimensions of the coil required, as well as any special instructions regarding packaging and delivery.

Manufacturers usually require you to pay 50% of the order value upfront, with the remaining 50% to be paid upon delivery.

Step#4 Production Process and Quality Checks

Once your order has been placed, the supplier will begin the production process. Depending on the size and complexity of the order, this can take anywhere from a few days to several weeks. During production, regular quality checks will be carried out to ensure that the coils meet your specifications.

Step#5 Delivery and Feedback

Once production is complete, the pre-painted aluminum coils will be delivered to your specified address. Upon receipt, it is important to inspect the goods and make sure that they meet your quality standards.

If you are satisfied with the products, be sure to provide feedback to the supplier so that they can continue to improve their service.

7. 5 Tips to Find a Reputable Manufacturer

When looking for a pre-painted aluminum coil manufacturer, there are a few things you should keep in mind. Here are 5 tips to help you find a reputable prepainted aluminum coil factory:

#1 ISO 9001 certified

ISO 9001 is an international quality management standard that helps organizations ensure that their products and services meet customer and regulatory requirements. A pre-painted aluminum coil manufacturer that is ISO 9001 certified has a proven commitment to quality and customer satisfaction.

#2 Warranty

A reputable prepainted aluminum coil supplier will offer a warranty on their products. This shows that the manufacturer is confident in the quality of their products and is willing to stand behind them.

#3 Long Track Record

When it comes to pre-painted aluminum coils, you want to make sure you’re working with a pre-painted aluminum coil factory that has a long track record of producing high-quality products. A manufacturer with a long track record is likely to have a better understanding of the market and what customers are looking for.

#4 Customer Testimonials

Customer testimonials are a great way to get an idea of what it’s like to work with a particular pre-painted aluminum coil manufacturer. Ask around to see if anyone you know has worked with the manufacturer before and see what they have to say.

Do not just settle for customers’ feedback on the prepainted aluminum coil manufacturer’s website. Make sure to read through reviews and testimonials carefully to get a well-rounded idea of what the manufacturer is like to work with.

#5 Competitive Pricing

While price shouldn’t be the only factor you consider when choosing a pre-painted aluminum coil manufacturer, it’s important to make sure you’re getting a competitive price. Get quotes from several different pre-painted aluminum coil suppliers before making your final decision.

8. The Average Cost of Pre-painted Aluminium Coil

The average cost of the pre-painted aluminium coil range from $2,000 to $3,500 per metric ton. This cost varies greatly depending on the supplier you choose. It will also depend on many factors such as:

- Quantity of pre-painted aluminum coil you need

- Size and dimensions of the pre-painted aluminum coil

- The type of paint used

- Any additional treatments or processes required

- Any additional costs associated with pre-painted aluminium coil

9. 6 Buying Tips for Pre-painted Aluminium Coil

There are many factors to consider when purchasing a pre-painted aluminium coil. Here are 6 tips to help you make the best decision for your business:

#1 Type of Paint

There are a variety of paints that can be used to the pre-paint aluminium coil. The type of paint you choose will depend on the end use of the coil. If you are using the pre-painted aluminium coil for cladding or roofing, then you will need a different type of paint than if you are using it for gutters or downpipes.

#2 Color

The pre-painted aluminium coil is available in a wide range of colors. You can choose from standard colors or opt for a custom one. You need to ensure that the color you choose is compatible with the other materials you’ll be using it with.

#3 Finish

The pre-painted aluminum coil is available in a variety of finishes. You can choose from glossy, matte, or even textured finishes. The finish you choose will depend on the end use of the coil. For example, automotive parts require a different type of finish than building materials.

#4 Size and Dimensions

The pre-painted aluminium coil is available in a wide range of sizes and dimensions. You need to make sure that you’ll buy enough coil to cover the entire surface area you need.

#5 Thickness

Depending on what you plan to use it for, the thickness of the coil you choose will vary. It will also affect how much money you spend, so be sure to get your money’s worth.

#6 Treatment and Processes

Before it’s ready to be utilized, the pre-painted aluminum coil must go through many treatments and processes. These include degreasing, deoxidizing, annealing, and more. Make sure you understand all of the steps in the procedure so that you can choose the best coil for your business.

Here’s a video of a annealing process of an aluminium, check this out!

10. Conclusion

Pre-painted aluminum coils are versatile and durable products that can be used for many different purposes. To ensure that you choose the best coil for your needs, you need to find a reputable manufacturer that can provide you with a high-quality product.

We at Upaluminum, have years of experience and expertise in the aluminum manufacturing industry. We use the latest technology and equipment to produce our products. Our pre-painted aluminum coils meet all the international standards and are available in a variety of colors, sizes, and thicknesses.

Contact us today to learn more about our products and how we can help you find the perfect pre-painted aluminum coil for your business.